Restoring airbags and sensors in vehicles demands a meticulous process focused on safety and functionality. This involves thorough inspections, disassembly for detailed examination, and skilled technicians using specialized tools to verify repair quality against industry standards. Reputable auto collision centers employ state-of-the-art equipment and strict protocols, ensuring restored parts function effectively. The ultimate goal is to enhance road safety through rigorous repair quality verification, critical for driver and passenger protection.

Airbag and sensor restoration is a critical process ensuring vehicle safety. As these systems play a vital role in passenger protection, proper repair and reconstruction are essential. This article explores the intricate steps of the restoration process, highlighting the significance of implementing robust repair quality verification techniques. We will delve into effective strategies that automotive professionals can employ to guarantee the safety and reliability of restored airbags and sensors, ultimately safeguarding drivers and passengers alike.

- Understanding Airbag and Sensor Restoration Process

- Importance of Repair Quality Verification Techniques

- Effective Strategies for Ensuring Restored Component Safety

Understanding Airbag and Sensor Restoration Process

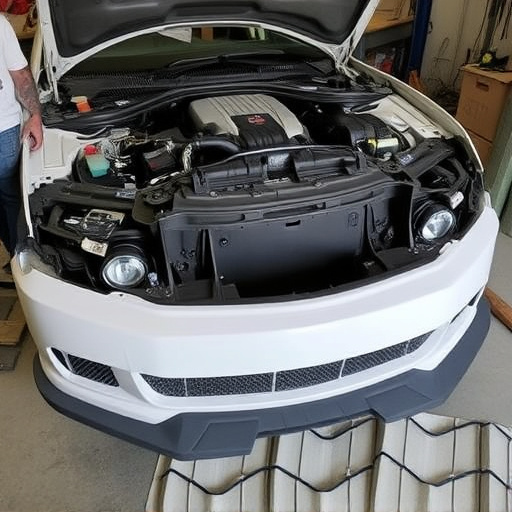

The process of restoring airbags and sensors in vehicles involves a meticulous series of steps aimed at ensuring safety and functionality. It begins with a thorough inspection to identify the extent of damage, followed by disassembly for detailed examination. This is where repair quality verification plays a critical role. Skilled technicians use specialized tools to assess each component, checking for any defects or discrepancies that could compromise performance. Every part, from inflators to sensors, undergoes rigorous testing to meet stringent industry standards.

Reputable auto collision centers employ state-of-the-art equipment and adhere to strict protocols for airbag and sensor restoration. This meticulous approach ensures not just visual repairs like a vehicle dent repair but also the reliability of safety systems. Through this comprehensive process, these centers guarantee that restored parts function as effectively as new ones, enhancing road safety for all vehicles leaving their facilities, be it an auto body repair or a more complex restoration project.

Importance of Repair Quality Verification Techniques

In the intricate process of airbag and sensor restoration for cars, ensuring repair quality verification is paramount to safety and reliability. These components play a critical role in modern vehicles’ active safety systems, deploying in milliseconds during collisions to protect occupants. Thus, meticulous attention must be given to every step of the restoration process. Repair quality verification techniques act as a robust safeguard, ensuring that each part meets the highest standards for functionality and integrity.

This verification process involves a multifaceted approach, encompassing rigorous testing, precision calibration, and meticulous visual inspections. By employing these methods, technicians can identify and rectify any discrepancies or damage, be it from a minor fender bender or extensive tire services. The goal is to restore not just the physical components but also the confidence in their performance, vital for the well-being of drivers and passengers alike.

Effective Strategies for Ensuring Restored Component Safety

Ensuring the safety and reliability of restored components is paramount in the automotive industry, especially for critical systems like airbags and sensors. One effective strategy is to implement a rigorous repair quality verification process that mimics the original manufacturing standards. This involves meticulous inspection protocols using advanced diagnostic tools to identify and rectify any discrepancies. At top-tier car repair shops, such as those specializing in Mercedes-Benz collision repair, this may include checking for proper functionality, component integrity, and adherence to strict tolerances.

Moreover, a comprehensive training program for technicians is vital. Keeping up with the latest industry standards and technologies specific to luxury vehicle repair ensures that repairs are not just functional but also safe. Regular audits and quality control measures further bolster the process, enabling continuous improvement and maintaining high safety standards. These strategies collectively contribute to restoring not just the physical components but also the confidence of drivers who rely on these critical systems in emergency situations.

Repair Quality Verification (RQV) is an indispensable aspect of the Airbag and Sensor Restoration process, ensuring restored components meet safety standards. By employing effective RQV strategies, we can maintain the integrity and reliability of these critical systems, ultimately fostering road safety and public confidence. This holistic approach, encompassing a deep understanding of restoration processes and advanced verification techniques, guarantees that every repaired component performs optimally, saving lives and enhancing the overall automotive industry’s reputation.