Repair Quality Verification: Enhancing Shop Accountability

Repair Quality Verification (RQV) is a critical process in the automotive industry, ensuring high-qu…….

Welcome to an in-depth exploration of a critical process that plays a pivotal role in various industries worldwide—Repair Quality Verification (RQV). This comprehensive guide aims to demystify RQV, highlighting its significance, methodologies, and impact on ensuring optimal repair and maintenance standards. By the end of this article, readers will have a thorough understanding of how RQV shapes the quality of services offered by maintenance professionals across sectors, from manufacturing to healthcare.

Repair Quality Verification (RQV) is a systematic process designed to assess and ensure the quality of repair and maintenance work performed on various products, equipment, or facilities. It involves multiple stages, including planning, inspection, testing, documentation, and feedback, to guarantee that repairs meet predetermined standards. The primary goal of RQV is to identify defects, non-conformities, or variations from the specified requirements early in the repair process, allowing for immediate corrective actions.

The concept of RQV has evolved over time, driven by the increasing complexity of machinery and equipment and the growing demand for high-quality services across industries. Historically, repairs were often carried out with less emphasis on quality control, resulting in subpar work that led to costly failures and safety hazards. However, with advancements in technology and a shift towards precision manufacturing, RQV became an integral part of modern maintenance practices.

In the early 1900s, the automotive industry pioneered some of the earliest forms of RQV, implementing basic inspection and testing procedures to ensure vehicle reliability. As industries like aerospace, electronics, and healthcare emerged, so did the need for more sophisticated RQV methods to address unique challenges associated with these sectors. Today, RQV is a critical component in quality management systems worldwide, adhering to international standards such as ISO 9001 and AS9100 for the aviation industry.

RQV’s importance lies in its ability to:

Prevent Costly Failures: By identifying issues early, RQV reduces the likelihood of equipment failures during operation, minimizing downtime and associated costs.

Enhance Safety: Ensuring repairs meet quality standards contributes to safer working environments, particularly in high-risk industries like oil and gas, where equipment failure can have severe consequences.

Maintain Compliance: Many industries are subject to strict regulations, and RQV helps organizations meet these requirements, avoiding legal penalties and potential reputational damage.

Improve Customer Satisfaction: Consistent application of RQV leads to higher-quality services, fostering customer trust and loyalty.

RQV’s influence is not limited to any specific region; it is a global phenomenon with a significant impact across all continents. The adoption and implementation of RQV practices vary among countries due to cultural, economic, and regulatory differences, but its underlying principles remain consistent.

North America: Known for its advanced manufacturing sector, the United States leads in RQV innovation, with many industry leaders adopting cutting-edge technologies like digital inspection and AI-driven quality analysis. Canada, too, has a robust RQV framework, heavily influenced by its strong automotive and aerospace industries.

Europe: With a strong emphasis on health and safety standards, European countries have stringent RQV regulations, especially in industries like pharmaceuticals and medical device manufacturing. The EU’s strict product safety guidelines play a significant role in shaping RQV practices across the region.

Asia-Pacific: This region, particularly Japan and South Korea, has become a hub for technological advancements in RQV, including the adoption of robotics and automated testing systems to enhance efficiency and accuracy. China, with its massive manufacturing base, is rapidly improving its RQV standards to meet global demands.

Middle East and Africa: While these regions may have varying levels of RQV implementation, there is a growing recognition of its importance, especially in sectors like oil and gas, where high-quality repairs are critical for safety and operational efficiency.

Digitalization: The rise of Industry 4.0 has revolutionized RQV through the integration of digital technologies, enabling real-time data analysis, remote monitoring, and advanced predictive maintenance.

Standardization: International standards organizations like ISO and IEC are working towards harmonizing RQV practices globally, making it easier for companies to implement consistent quality control measures across borders.

Sustainability Focus: There is a growing emphasis on environmentally friendly RQV methods, with industries exploring ways to minimize waste, reduce energy consumption, and adopt sustainable materials during repair processes.

The global RQV market has experienced steady growth due to the increasing demand for high-quality services across various sectors. According to a 2022 report by ResearchAndMarkets.com, the market size is projected to reach $14.5 billion by 2027, growing at a CAGR of 8.2% during the forecast period (2022-2027). This growth can be attributed to:

Industries investing heavily in RQV include:

Aerospace: With stringent safety standards and complex equipment, the aerospace industry leads in RQV spending, ensuring aircraft repairs meet exacting specifications.

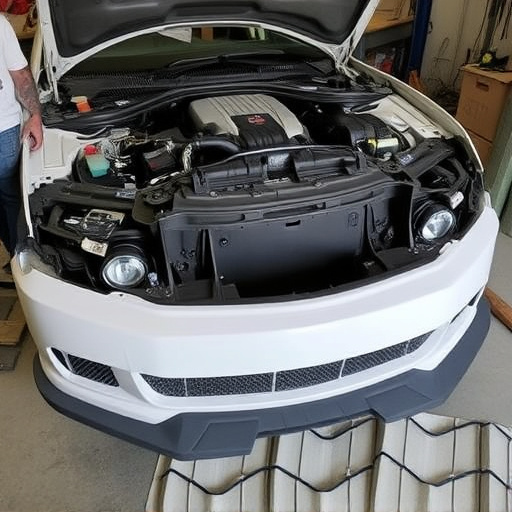

Automotive: The global automotive market’s focus on precision manufacturing and quality control has driven significant investments in RQV technologies, particularly for electric vehicle (EV) repair and maintenance.

Healthcare: Medical device manufacturers and healthcare facilities are investing in RQV to maintain patient safety and ensure medical equipment meets regulatory standards.

Effective RQV practices contribute to:

Cost Reduction: Identifying defects early prevents costly rework, minimizing waste, and optimizing material usage.

Increased Productivity: Streamlined RQV processes enable faster turnaround times, allowing maintenance teams to handle more tasks efficiently.

Enhanced Competitiveness: Organizations known for their rigorous RQV standards gain a competitive edge, attracting customers who prioritize quality and reliability.

Digital inspection technologies have revolutionized RQV by providing detailed, visual evidence of repair work. High-resolution cameras, 3D imaging, and computer vision algorithms enable inspectors to capture precise images, measure dimensions, and identify defects with unprecedented accuracy. This technology streamlines the documentation process, reduces human error, and provides a permanent digital record for future reference.

Automated testing systems, including robotic arms and AI-driven software, are transforming RQV by performing repetitive tasks with precision and speed. These systems can handle complex inspections, fluid dynamics testing, and material property analysis, freeing up human resources to focus on more specialized tasks. The integration of AI algorithms enhances defect detection, enabling systems to learn and adapt to new defects as they arise.

Predictive maintenance leverages sensor data, machine learning, and historical repair records to anticipate equipment failures before they occur. By continuously monitoring equipment health, organizations can schedule repairs during planned maintenance windows, minimizing unplanned downtime. This technology is particularly valuable in industries like manufacturing, where critical machinery needs continuous uptime to remain competitive.

AR and VR technologies offer immersive training environments for RQV personnel, enabling them to practice complex inspection and repair procedures without risking actual equipment or materials. AR can also provide real-time guidance during repairs, overlaying digital instructions on the physical work environment, thus improving efficiency and accuracy.

International standards organizations play a crucial role in defining global RQV practices:

ISO 9001: This widely adopted standard provides guidelines for quality management systems, including RQV as a critical component. It ensures consistent service delivery and customer satisfaction.

AS9100: Specific to the aerospace industry, AS9100 sets rigorous standards for quality management in aviation, space, and defense organizations, with a strong emphasis on process control and RQV.

IEC 62079: This standard focuses on electrical equipment maintenance and provides guidelines for RQV practices in this domain.

In addition to international standards, various regions have implemented specific regulations:

United States (OSHA): The Occupational Safety and Health Administration sets safety standards, including those related to RQV, to protect workers in repair and maintenance industries.

European Union (EU) Directives: EU legislation covers product safety, machinery directives, and health and safety at work, all of which influence RQV practices across the continent.

Japan (JIS): The Japanese Industrial Standards include guidelines for quality assurance and control, aligning with global best practices in RQV.

Legislative frameworks ensure that organizations adhere to RQV standards:

Licensing and Certification: Many countries require repair facilities to obtain licenses or certifications, demonstrating their competence in RQV processes.

Audits and Inspections: Regular audits by government bodies or third-party inspectors ensure compliance with RQV regulations and international standards.

Penalties for Non-Compliance: Organizations found non-compliant with RQV regulations may face fines, legal action, or damage to their reputation.

Skill Shortage: There is a global shortage of skilled RQV professionals, particularly as industries become more specialized and technology advances.

Cost Implementation: Implementing advanced RQV technologies can be expensive, posing challenges for smaller organizations or those with tight budgets.

Data Management: As RQV processes generate vast amounts of data, efficient storage, retrieval, and analysis become critical issues, requiring robust digital infrastructure.

Subjectivity in Inspection: Critics argue that manual inspection can be subjective, leading to variations in quality assessment. To address this, organizations should invest in standardized training programs and implement digital inspection tools for consistent results.

Time Consumption: Some RQV processes can be time-consuming, particularly complex inspections. Automating repetitive tasks and leveraging AI for real-time analysis can significantly improve efficiency.

Lack of Standardization: Inconsistencies in RQV practices across industries and regions create challenges in comparing performance and sharing best practices. Standardization efforts by international organizations can help overcome this issue.

Boeing, a global aerospace giant, employs extensive RQV procedures for its aircraft maintenance and repair. They utilize advanced digital inspection tools, including 3D laser scanning and computer vision systems, to ensure every component meets exacting specifications. Boeing’s predictive maintenance systems analyze sensor data from aircraft to anticipate maintenance needs, minimizing downtime and enhancing safety.

Toyota Motor Corporation has implemented a comprehensive RQV system for its global vehicle repair network. Their approach includes standardized training programs for technicians, digital documentation, and real-time data analysis to optimize repair times and quality. Toyota’s use of AI-driven quality control has led to a significant reduction in defect rates and improved customer satisfaction.

GE Healthcare, a leader in medical technology, employs rigorous RQV practices for its global device repair operations. They use automated testing systems to ensure the functionality and safety of critical medical equipment. GE’s digital quality management platform enables remote monitoring, data analysis, and rapid issue resolution, enhancing patient safety and maintaining regulatory compliance.

AI and Machine Learning: Advanced AI algorithms will continue to revolutionize RQV by automating complex defect detection, predictive modeling, and quality prediction.

Remote and Digital Inspection: The rise of remote inspection technologies, powered by 5G and IoT, will enable experts to provide real-time guidance from distant locations, increasing accessibility and reducing costs.

Sustainability Focus: As environmental concerns grow, RQV practices will increasingly emphasize sustainable materials, processes, and waste reduction strategies.

Blockchain for Quality Tracking: Blockchain technology can ensure transparent and secure data sharing, enabling organizations to track product lifecycles and repair history, enhancing accountability and traceability.

Collaborative Quality Control: The future may see more collaboration between maintenance teams, suppliers, and customers through shared digital platforms, fostering transparency and continuous improvement.

Real-Time Quality Monitoring: IoT sensors integrated into equipment can provide real-time data for proactive quality control, enabling predictive maintenance and reducing unplanned downtime.

In conclusion, Repair Quality Verification is a cornerstone of modern maintenance and repair practices, ensuring excellence across diverse industries worldwide. As technology advances and global standards evolve, RQV will continue to adapt and grow, addressing new challenges and opportunities. By embracing innovative solutions and adhering to best practices, organizations can maintain the highest quality standards, enhance customer satisfaction, and drive operational efficiency.

Q: How does RQV differ from traditional quality control?

A: While both focus on ensuring quality, RQV is a more comprehensive and systematic process, involving multiple stages of inspection, testing, and documentation. It goes beyond basic visual inspections to include advanced technologies and data analysis for more accurate defect detection.

Q: What role does digital transformation play in modern RQV?

A: Digital transformation revolutionizes RQV through the integration of digital tools like computer vision, AI, and IoT. These technologies enable real-time data analysis, remote inspection, automated testing, and efficient documentation, enhancing accuracy, speed, and accessibility.

Q: How can organizations ensure consistent RQV across multiple locations?

A: Consistency can be achieved through standardized training programs, implementing international standards (e.g., ISO 9001), and utilizing digital quality management systems that facilitate remote monitoring and data sharing. Regular audits and benchmarking against industry best practices also contribute to maintaining consistent quality.

Q: What are the key benefits of adopting advanced RQV technologies?

A: Advanced technologies offer numerous advantages, including improved accuracy in defect detection, reduced inspection times, increased productivity, enhanced safety through predictive maintenance, and better data-driven decision-making for continuous improvement.

Q: How can small businesses with limited budgets implement effective RQV practices?

A: Small businesses can start by prioritizing basic digital tools, such as cameras and documentation software, to streamline manual inspection processes. They should also consider outsourcing specialized services and leveraging industry best practices and resources available through trade associations or government agencies.

Repair Quality Verification (RQV) is a critical process in the automotive industry, ensuring high-qu…….

Repair Quality Verification (RQV) is essential for collision centers and car body shops to ensure re…….

A meticulous pre-repair assessment is crucial for identifying potential issues, developing a compreh…….

Repair Quality Verification (RQV) is a rigorous process ensuring auto body repairs meet high standar…….

Understanding repair scope and objectives through damage reports, expert consultations, and defining…….

In a competitive auto industry, repair quality verification is key to building customer trust and lo…….

A thorough understanding of project scope and objectives, including damage assessment, desired outco…….

Repair Quality Verification (RQV) is a stringent evaluation process ensuring vehicles meet high stan…….

Repair Quality Verification (RQV) is key to assessing and ensuring high-quality car repairs, especia…….

Advanced digital tools revolutionize repair quality verification in car body shops and collision cen…….