Understanding project scope and objectives, defining repair specifics, setting achievable checkpoints, and establishing quality standards are crucial for effective repair quality verification. Tailored inspection procedures cover each stage, from visual inspections to rigorous testing, ensuring consistent quality for customer satisfaction. Skilled technician involvement and advanced diagnostic tools maintain high industry standards in auto body repairs.

In the realm of maintenance and upkeep, effective repair quality verification (QR) processes are paramount for ensuring exceptional outcomes. This article guides you through a meticulous approach, focusing on three key steps: understanding the repair scope and objectives, implementing detailed QR procedures, and conducting comprehensive testing and analysis. By adhering to these strategies, professionals can guarantee that repairs meet or exceed industry standards, fostering longevity and reliability across diverse sectors.

- Understand Repair Scope and Objectives

- Implement Detailed Verification Procedures

- Conduct Thorough Testing and Analysis

Understand Repair Scope and Objectives

Before initiating any repair quality verification process, it’s imperative to gain a deep understanding of the project scope and objectives. This involves clearly defining what needs to be repaired, whether it’s a simple engine tune-up or complex frame straightening in an auto collision center. The scope should encompass all aspects, including parts replacement, technical specifications, and customer expectations. Knowing the end goal is crucial for setting realistic verification checkpoints and establishing successful quality standards.

For instance, when dealing with auto repair services, understanding the project may involve assessing the extent of damage after an accident, consulting with insurance providers, and understanding the customer’s specific needs. This foundational knowledge ensures that every step of the verification process aligns with achieving high-quality repairs, from ensuring precise frame straightening to selecting top-tier replacement parts.

Implement Detailed Verification Procedures

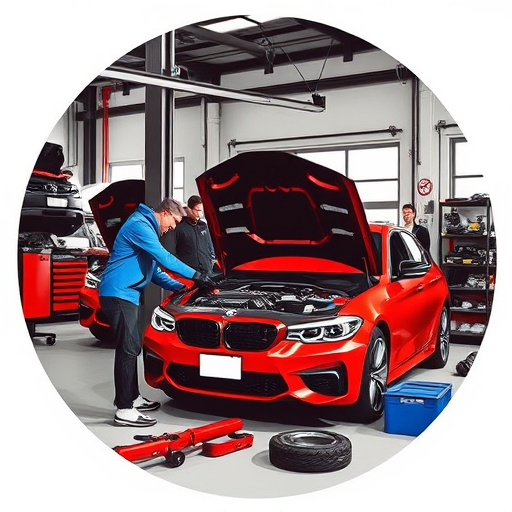

To ensure effective repair quality verification, it’s crucial to implement detailed verification procedures tailored to specific repair tasks. These procedures should encompass comprehensive inspection protocols for every stage of the repair process. For instance, in a car body shop handling car scratch repairs, verification could involve visually inspecting each panel for alignment, paint consistency, and the absence of visible defects before clear coating or final painting. This meticulous approach guarantees that even subtle issues are captured early on.

For fleet repair services where efficiency is paramount, standardized checklists can streamline the verification process. These checklists should be designed to ensure every repair adheres to quality standards, regardless of the complexity or type of damage—whether it’s a minor dent removal or significant structural repairs. By systematically checking each item on the checklist, mechanics and supervisors can maintain high repair quality, enhancing customer satisfaction and the overall reputation of the car body shop.

Conduct Thorough Testing and Analysis

In the context of repair quality verification processes, conducting thorough testing and analysis is a critical step to ensure optimal results in auto body repair or collision repair scenarios. This involves utilizing advanced diagnostic tools and employing skilled technicians to meticulously inspect the repaired vehicle. Every component, from structural integrity checks to aesthetic considerations, is evaluated to match the original equipment specifications.

The process encompasses various sub-tests, such as paint analysis, panel alignment, and functional assessments of electronic systems. In auto maintenance, this comprehensive testing serves as a quality control measure, identifying any deviations from the standard repair procedures. By implementing rigorous analysis, repair facilities can guarantee that the final product meets or exceeds industry benchmarks, ensuring customer satisfaction in both auto body repair and collision repair services.

Effective repair quality verification processes involve a meticulous understanding of the repair scope and objectives, coupled with detailed verification procedures. Once these are in place, thorough testing and analysis ensure that every aspect of the repair meets the desired standards. By adhering to these steps, organizations can guarantee high-quality repairs, fostering customer satisfaction and maintaining operational efficiency.