A thorough understanding of project scope and objectives, including damage assessment, desired outcomes, and customer expectations, is crucial for repair quality verification. Detailed procedures, checklists, and tailored verification processes ensure excellence in repairs, particularly complex ones like paintless dent repair and Mercedes Benz collision repair. Rigorous inspections, alignment checks, and advanced diagnostics guarantee each repair meets impeccable standards, aiming to restore vehicles to pre-incident condition and prioritize customer satisfaction.

In the realm of maintenance and restoration, ensuring repair quality verification (RQV) is paramount. This comprehensive guide outlines crucial steps for achieving flawless results. Begin by clearly understanding the repair scope and objectives, serving as a compass for the entire process. Next, implement detailed verification procedures tailored to each project’s unique demands. Subsequently, conduct rigorous testing and validation, ensuring every aspect meets the desired standards. By adhering to these steps, professionals can deliver exceptional RQV, guaranteeing customer satisfaction.

- Understand Repair Scope and Objectives

- Implement Detailed Verification Procedures

- Conduct Thorough Testing and Validation

Understand Repair Scope and Objectives

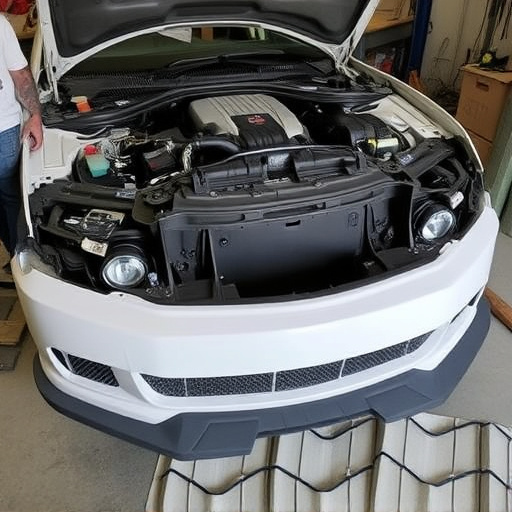

Before initiating any repair quality verification process, it’s essential to have a clear understanding of the project’s scope and objectives. This involves meticulously reviewing the extent of damage sustained by the vehicle, whether it’s as simple as an auto glass replacement or complex car collision repair involving multiple components. The verification team must grasp the desired outcome, ensuring it aligns with industry standards and customer expectations.

In the context of vehicle collision repair, defining the scope could mean assessing structural integrity, cosmetic repairs, and even ensuring safety features are operational. This step is crucial as it guides the verification process, dictating which aspects require rigorous scrutiny. A comprehensive grasp of the objectives ensures every detail, from aligning panels in auto glass replacement to checking paint job perfection in car collision repair, meets the required standards.

Implement Detailed Verification Procedures

In the realm of repair quality verification, implementing detailed procedures is a cornerstone of excellence. This involves meticulously planning and executing checks at every stage of the repair process. For instance, in a car repair shop handling intricate tasks like paintless dent repair, each step from initial assessment to final touch-ups requires precise documentation and verification. Comprehensive checklists ensure no detail is overlooked, thereby guaranteeing restoration accuracy for vehicles undergoing meticulous transformations.

These verification procedures should be tailored to the specific services offered, focusing on key aspects unique to each task. For vehicle restoration projects, this might mean scrutinizing paint job uniformity, ensuring seamless body panel alignment in every angle, and verifying that all components are functioning optimally after repair. Such meticulous attention to detail not only ensures superior repair quality but also cultivates customer satisfaction and builds trust in the car repair shop’s capabilities.

Conduct Thorough Testing and Validation

In the realm of repair quality verification, conducting thorough testing and validation is a non-negotiable step for achieving excellence in Mercedes Benz collision repair or any vehicle paint repair. This involves meticulous inspection of the repaired area, ensuring alignment, fit, and finish are flawless. Advanced diagnostic tools can be employed to verify structural integrity and identify any subtle issues that may have been overlooked during the repair process.

The goal is to ensure the repaired vehicle meets the highest standards, matching its pre-incident condition as closely as possible. This comprehensive validation process plays a pivotal role in maintaining customer satisfaction and ensuring the safety of the road. Whether it’s collision repair or more specialized vehicle paint repair, rigorous testing guarantees that no detail is left unturned, delivering a superior quality outcome every time.

Effective repair quality verification processes involve a structured approach, beginning with a clear understanding of the repair scope and objectives. This is followed by the implementation of detailed procedures tailored to the task at hand. Subsequent steps include conducting thorough testing and validation, ensuring every aspect meets the desired standards. By adhering to these steps, organizations can ensure comprehensive repair quality verification, fostering efficiency and customer satisfaction.